Pallet Stamps – What are they made of and How are they made?

Stamp Types and Materials

We’ve had some questions regarding Pallet/Lumber Stamps – here are some answers…

What are the styles of Pallet Stamps?

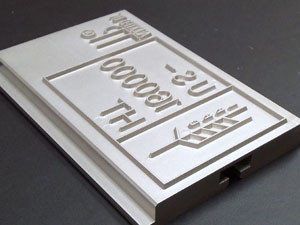

There are several styles of stamps currently being used for marking pallets to indicate pallets have been heat treated, meet IPPC requirements and or are for dunnage. The most common sizes produced for stamps are 1 ¼” x 2 1/8” and 2” x 4” but stamps can be made to any size to fit the application

- There are rubber stamps that are inked before use with a separate ink pad, these can be supplied with a flat mount or a rocker mount for larger sizes, along with various styles of handles or knobs. Some are also supplied as a hammer stamp

- There are self-inking styles of stamps, these will have an ink pad as part of the stamp and will ink the die while being used. They can be supplied as an upright style, commonly referred to as a grocery stamp, or as a roller stamp where the image is rolled on.

Which type of Rubber is best for Pallet Stamps?

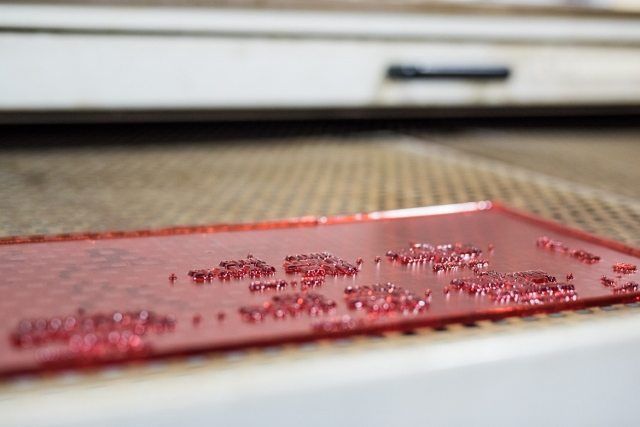

There are different types of rubber used to make the stamp dies, natural rubber and buna rubber, and some people will use photopolymer to make the stamp dies. All provide different characteristics and benefits. Ink choice needs to be considered when choosing the rubber type used

- Natural rubber is the most used. Latex based; it will provide a softer material surface that’s helps provide a better image on a rough wood surface. Natural rubber can also be supplied with a ribbed back that will be used to snap and hold into place on the stamp mount, making it easier to change dies when they wear out. Good abrasion resistance and tear resistance, fair solvent, and oil resistance.

- Buna rubber is a harder durometer material. It is a synthetic material that will be more resistant to the corrosive ingredients in the inks used. While it will hold up better, the harder surface makes it less forgiving when stamping a rough surface, it will not be as conforming when stamped. Excellent abrasion resistance, good solvent, and tear resistance

- Photopolymer is a synthetic polymer. While it may provide the best image quality, it is also the most susceptible to abrasion and environmental (ozone) issues. Poor abrasion resistance, fair tear, and solvent resistance.

What type of Ink should be used with Pallet Stamps?

There are several types of inks used for stamping wood.

- Rubber stamp ink, it is used for stamp pads and for self-inking stamps, it will have a slower dry time to avoid drying out on the pads, lower solvent (alcohol) content, designed for use with natural and buna rubber. Higher in cost.

- Stencil ink, quick drying. Used by many in the pallet industry because it is lower in cost, but it is much higher in alcohol content and will cause the stamp dies to swell, become gummy, and produce a lower quality image.

This information does not cover all the stamp styles and materials available but includes the most commonly used. Every application can be different, we hope this will provide a good reference for you when deciding what best fits your need.

EMAIL SALES@EXCELSIORMARKING.COM to learn more.