Pallet Identification – Brand, Stencil and Stamp

Call it Marking, Stamping or identifying; every Wood Pallet and/or Plastic Pallet that travels globally must be marked with an ISPM approved mark. The International Standards for Phytosanitary Measures – ISPM mandates this fact. The reasons for the mark is clear – to reduce the risk of the introduction and spread of pests, via wood pallet. Each item must be treated either by Heat Treatment or Chemical Treatment (Methyl Bromide). The problem arises when the “How” to mark the Pallet comes into play.

The Mark, indicating treatment, varies by country. In general it will include:

-The symbol (IPPC)

– Country Code

– Certification Agency Code

– Treatment code (HT or MB)

Always check with your Certifying Agency for the exact standard.

From these guidelines, the search for the perfect marking solution was born. The challenge is to find a method that will work in a dusty, outside environment. In addition, depending on where the Pallet manufacturer is located, air temperature may need to be considered. There are a few major ways to mark wood pallets. All have advantages and disadvantages. They include Branding, Stenciling or Stamping.

Branding

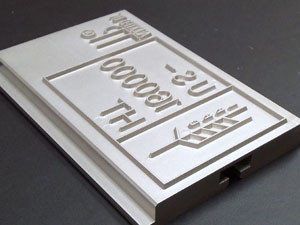

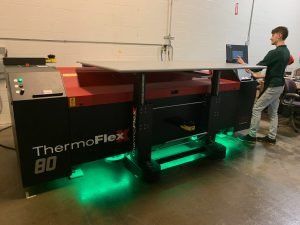

Branding uses a Iron with a heated, metal die to burn an imprint into the pallet. Heavy duty Branding Irons can be hand held or machine mounted. Branding creates a solid impression. Generally the brand will include the two letter country code (e.g. DE for Germany), the regional identifier (e.g. NW for North Rhine-Westphalia) and a registration number issued by the regional phytosanitary authority to the packaging container manufacturer, the packer or the consignor (unique number beginning with a logo. Learn more about the approved mark from your certifying agency. Custom branding dies are made of steel or hard metal that can withstand the high temperatures. Electric and Propane Branding Irons come in different wattages. A higher watt iron will allow a quicker process, with less down time. Branding entails more of an investment than stamps or stencils. All dies are custom machined, and the heavy duty Branders are also an investment. Once set up to Brand, the equipment can last several years.

Stamping

First, and probably, most common is marking with a Rubber Stamp. There are several types of rubber stamps; knob handle, self inking, and roller. The image is clear and visible, and with proper care, the stamp is a good solution. However, the process can be relatively slow since each pallet is stamped individually.

Stenciling

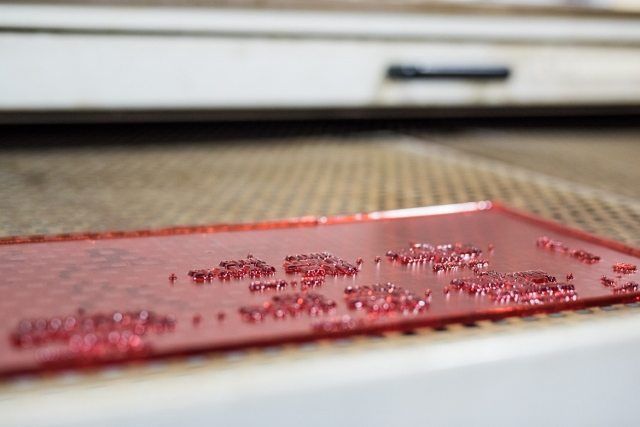

Stenciling is another solution for marking wood pallets. A laser cut, custom stencil is positioned on the pallet; Ink or paint is applied; and the stencil is removed. When applied carefully, a good mark can be achieved.

e best solution to marking pallets and lumber. The printer can be programmed from a PC and allows wireless marking. Printing is quick and consistent. For larger operations, inline printers can be machine mounted. This option does require an investment and a more “innovative” business philosophy. One early adopter had this to say; (the hand held printer) has “given us the ability to quickly mark our pallet and crating products with very little effort… Markings are clean and clear, showing a professional look our customer base now demands.” There has also been some resistance to accept the printed marks by some in the Pallet Industry, but that seems to be subsiding as more Hand Held Printers are used.